You know, sometimes I catch myself just staring at the sky, or examining a beautifully crafted metal piece, and I’m genuinely awestruck. It’s incredible how the ancient art of metalworking, honed over millennia, is now literally propelling us into the cosmos, shaping the very future of aviation and space exploration.

From groundbreaking new alloys designed to withstand unimaginable extremes to revolutionary 3D-printed rocket parts, the synergy between metal craftsmanship and the aerospace industry isn’t just advancing; it’s radically transforming what we thought was possible.

This fusion of tradition and cutting-edge innovation is something I’ve personally found incredibly inspiring. Stick around, because we’re about to explore how these phenomenal advancements are literally building tomorrow’s world.

The Unseen Heroes: Revolutionizing Flight Through Material Innovation

You know, it’s funny, we often look up at a soaring jet or a rocket blasting off and marvel at the sheer power, the engineering feat. But what we don’t always see, what truly astounds me, is the incredible artistry and science behind the materials themselves.

It’s like these metals are the unsung heroes, silently bearing immense stresses, temperature extremes, and unimaginable forces, all while keeping us safe.

When I think about the progress we’ve made, going from early aluminum structures to today’s exotic composites and advanced alloys, it truly feels like we’re living in a sci-fi novel.

This isn’t just about making things stronger; it’s about making them smarter, lighter, and more resilient than anyone thought possible just a few decades ago.

Every single advancement in flight, from that first wobbly flight to cruising at the edge of space, has been fundamentally underpinned by a breakthrough in metallurgy.

It’s a continuous quest for perfection, where the smallest improvement in material properties can mean the difference between a minor hiccup and a catastrophic failure.

The dedication to this often-invisible work is just breathtaking.

When Every Ounce Counts: Lightweighting for Efficiency

I’ve always been fascinated by how engineers obsess over weight, especially in aerospace. It’s not just a preference; it’s a critical design parameter that dictates everything from fuel efficiency to payload capacity.

Every kilogram saved translates directly into lower operational costs and a larger range, or the ability to carry more precious cargo. When I first started digging into this, I remember thinking, “How much difference can a few grams really make?” Oh, was I naive!

When you scale that up to the sheer size of a commercial airliner or a space rocket, those grams become tons, and the impact is monumental. This relentless pursuit of lightweight materials has led to some incredible innovations.

Think about it: materials that are not only lighter but also stronger than their predecessors. It’s like magic, but it’s pure, hard science and meticulous craftsmanship.

The balance act between strength, stiffness, and density is a constant challenge, pushing material scientists to invent new alloys and composites that redefine what we thought was possible.

It’s a testament to human ingenuity, really, seeing how they shave off ounces without ever compromising on safety.

Forging Resilience: Materials Engineered for Extreme Conditions

If you’ve ever imagined what it’s like inside a jet engine or what a spacecraft endures during re-entry, you’d quickly realize that ordinary metals just wouldn’t cut it.

We’re talking about temperatures that would melt steel, pressures that would crush a submarine, and corrosive environments that would dissolve almost anything.

What really gets me is the sheer audacity of designing materials that can not only survive these conditions but thrive in them for thousands of hours.

It takes a certain kind of genius, doesn’t it? Engineers are literally playing with atomic structures, creating alloys that exhibit properties that seem almost contradictory: incredibly strong yet flexible, heat-resistant yet lightweight.

I’ve seen documentaries where they talk about testing these materials, subjecting them to trials that mimic the most brutal environments imaginable, pushing them to their absolute breaking point and then beyond.

It’s a painstaking process, but it’s absolutely essential. Because when you’re thirty thousand feet up or hurtling through the vacuum of space, there’s no room for error.

The resilience forged into these materials is, in many ways, a reflection of the resilience of the human spirit to conquer the unknown.

Beyond Traditional Craft: The Dawn of Additive Manufacturing in Aerospace

I vividly remember the first time I saw a metal part being “grown” layer by layer in a 3D printer. My jaw literally dropped. For centuries, metalworking was about casting, forging, machining – subtractive processes where you start with a block and cut away what you don’t need.

But additive manufacturing, especially with metals, turns that whole paradigm on its head. It’s a complete game-changer, and it feels like we’re just scratching the surface of its potential in aerospace.

Imagine designing a component with an intricate internal lattice structure that’s impossible to create with traditional methods, yet is significantly lighter and stronger.

Now, imagine that part being built with almost zero waste. That’s the power we’re talking about here. It’s not just a new tool; it’s an entirely new philosophy of design and production that allows for unprecedented complexity and customization.

This technology is literally letting us dream up parts that were once confined to science fiction and bring them into reality, and I find that incredibly exhilarating.

Printing the Impossible: 3D-Metal’s Role in Rocketry

When you think about rocket engines, you probably picture massive, complex structures, right? They’re incredibly intricate, with fuel injectors, cooling channels, and turbine blades all working in perfect harmony under immense heat and pressure.

Traditionally, making these parts involved welding together dozens, sometimes hundreds, of smaller components. It was a painstaking, labor-intensive process with numerous potential points of failure.

But now, with 3D metal printing, companies are consolidating entire assemblies into a single, monolithic piece. I recently read about a rocket engine injector that was 3D printed, reducing over 200 individual parts into just one.

Think about the implications for reliability and manufacturing time! It’s mind-boggling. This isn’t just about efficiency; it’s about pushing the boundaries of what rockets can achieve, making them more powerful, more reliable, and ultimately, more affordable.

It truly feels like we’re witnessing a new space race, and 3D printing is one of its most powerful accelerators.

Precision Layer by Layer: Ensuring Structural Integrity

Of course, when you’re talking about parts that are going to propel people or satellites into space, “good enough” simply isn’t an option. The precision required in metal additive manufacturing for aerospace is absolutely insane.

We’re talking about depositing layers of metal powder mere microns thick, fused together with lasers or electron beams, with every single layer needing to be perfect.

The structural integrity of these components is paramount. I’ve heard stories about the rigorous testing these parts undergo – X-rays, CT scans, microscopic analysis – to ensure there are no hidden voids, no microscopic cracks, nothing that could compromise the part’s performance under extreme stress.

It’s a testament to the dedication of the engineers and technicians that they’re able to achieve such consistent, flawless results. They’re not just printing metal; they’re printing confidence, layer by painstaking layer.

The stakes are just too high for anything less than absolute perfection.

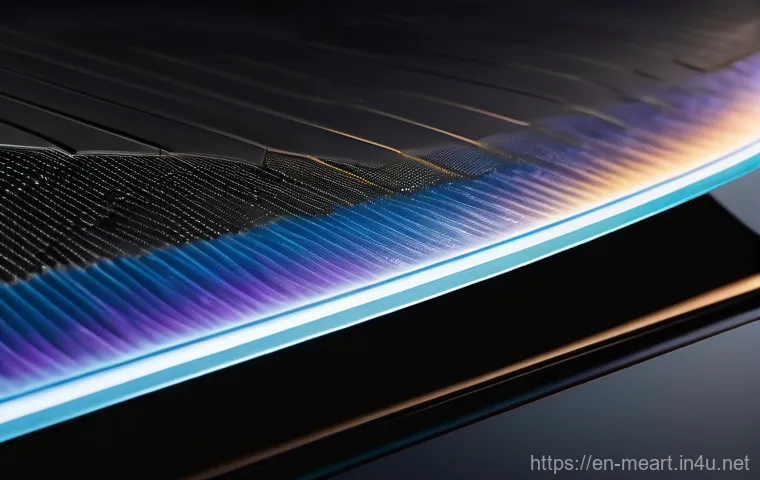

The Alchemy of Alloys: Crafting Supermaterials for Supersonic Speeds

It’s like a secret language, the way metallurgists talk about alloys. They’re not just mixing metals; they’re performing a kind of modern-day alchemy, carefully combining elements to unlock properties that none of the individual components possess.

When you look at the history of aviation, every major leap forward has been enabled by a new alloy. From the early days of strong aluminum for monoplanes to the exotic materials used in today’s stealth fighters and hypersonic vehicles, it’s a continuous story of material evolution.

I remember once trying to understand the phase diagrams and crystal structures, and my head started spinning! But the results are undeniable: materials that can withstand incredible forces, extreme temperatures, and corrosive environments, all while being surprisingly lightweight.

This meticulous blending and heat treating is where the real magic happens, transforming mundane elements into “supermaterials” capable of pushing the boundaries of speed and endurance.

Titanium’s Triumph: The Backbone of Modern Aviation

If there’s one metal that truly embodies the spirit of modern aerospace, for me, it’s titanium. It’s got this incredible strength-to-weight ratio, way better than steel, and it’s remarkably resistant to corrosion.

I’ve heard engineers lovingly call it the “workhorse” of the aerospace industry, and it’s easy to see why. From landing gear to engine components, structural frames to fasteners, titanium is everywhere in modern aircraft.

Its high melting point makes it ideal for areas exposed to extreme heat, like jet engine exhaust sections. The first time I held a piece of pure titanium, I was surprised by how light it felt for its apparent strength.

It feels robust, yet nimble. Its widespread adoption has been a slow and steady triumph, as it’s notoriously difficult to machine and work with, but the benefits in performance and longevity have proven absolutely worth the effort.

It truly is the silent backbone of so much of what flies today, enabling us to go higher, faster, and farther.

Nickel-Based Superalloys: Conquering the Heat Barrier

When you think about the incredible temperatures inside a jet engine’s combustion chamber, it’s mind-boggling that any material can survive there, let alone operate efficiently for thousands of hours.

That’s where nickel-based superalloys come into their own. These aren’t just strong; they maintain their strength and integrity at temperatures that would turn most other metals into molten puddles.

I’ve heard engineers describe them as the “holy grail” for hot sections of jet engines and gas turbines, and after learning about their properties, I totally get it.

They owe their incredible heat resistance to complex microstructures and special alloying elements that create a protective oxide layer at high temperatures.

It’s a sophisticated dance of chemistry and metallurgy. Working with these alloys requires specialized techniques, often involving vacuum melting and directional solidification, to achieve the desired crystalline structures.

It’s a highly specialized field, but the ability of these materials to conquer the heat barrier has been absolutely fundamental to the development of powerful, efficient, and reliable aircraft engines that define modern air travel.

From Blueprint to Boost: Ensuring Reliability in Critical Components

There’s an old saying in engineering: “Measure twice, cut once.” But in aerospace, it feels more like “Measure a thousand times, test a million times, then *maybe* you can cut once.” The journey from a conceptual design on a blueprint to a functional, reliable metal component that actually flies is absolutely mind-boggling in its rigor.

Every single piece, from the smallest fastener to the largest structural beam, undergoes an incredible gauntlet of scrutiny. What strikes me is the obsession with eliminating every possible point of failure.

It’s not just about meeting specifications; it’s about exceeding them, pushing the limits, and then building in safety margins on top of that. This isn’t just a technical exercise; it’s a profound commitment to safety and reliability that defines the entire industry.

When I think about the sheer volume of testing and verification, it truly instills confidence in the incredibly complex machines we entrust our lives to.

The Grueling Gauntlet: Testing Metals to Their Limits

I once visited a facility where they were doing fatigue testing on an aircraft wing section, and it was mesmerizing. They were essentially bending and twisting it repeatedly, thousands upon thousands of cycles, simulating decades of flight.

It was a stark reminder that simply being strong isn’t enough; materials also need to withstand countless cycles of stress without cracking or weakening.

This “grueling gauntlet” of testing is absolutely vital. We’re talking about everything from tensile strength tests, where materials are pulled until they break, to impact tests, where they’re subjected to sudden, violent forces.

Then there are vibration tests, acoustic tests, thermal cycling, and corrosion resistance evaluations. It’s not just about how the material performs in a pristine lab setting; it’s about how it behaves over its entire operational lifetime, under the most adverse conditions.

This meticulous, often destructive, testing provides the data points that allow engineers to confidently certify components for flight, ensuring they perform exactly as expected, every single time.

Why Flawless is Non-Negotiable: The Safety Imperative

In many industries, a small defect might mean a warranty claim or a minor inconvenience. In aerospace, a small defect can mean disaster. That’s why the concept of “flawless” isn’t just an aspiration; it’s an absolute non-negotiable imperative.

Every single weld, every fastener, every inch of metal is subjected to intense scrutiny, often using non-destructive testing methods like ultrasound, X-rays, and eddy current inspections.

I’ve always been amazed by the dedication to this level of quality control. It goes beyond mere compliance; it’s deeply ingrained in the culture of aerospace manufacturing.

The responsibility felt by everyone involved, from the metallurgist designing the alloy to the technician performing the final inspection, is palpable.

There’s a profound understanding that lives depend on their precision and their unwavering commitment to perfection. This shared sense of responsibility, I believe, is what truly elevates aerospace manufacturing to a league of its own, making it an incredible example of human trust and meticulous craftsmanship.

A Human Touch in a High-Tech World: The Artisans Behind the Machines

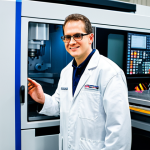

You know, for all the talk about AI and automation, there’s still an undeniable human element at the heart of advanced metalworking for aerospace. It’s not just about cold, hard data and algorithms; it’s about the experienced eye, the skilled hand, and the intuitive understanding that comes from years of working with these incredible materials.

I’ve had the privilege of meeting some of these artisans – engineers, welders, machinists – and their passion is infectious. They don’t just see a piece of metal; they see the potential, the challenge, and the responsibility.

It’s a beautiful blend of traditional craftsmanship and cutting-edge technology, where the human touch remains absolutely critical for achieving the kind of precision and reliability that aerospace demands.

We can automate many things, but the nuanced judgment, the problem-solving on the fly, and the deep expertise still require a human mind.

Where Expertise Meets Innovation: The Role of Skilled Engineers

It’s easy to focus on the dazzling technology, but behind every groundbreaking material or innovative manufacturing process are brilliant minds. These engineers are constantly pushing boundaries, experimenting with new compositions, refining processes, and solving problems that haven’t even been conceived of yet.

I’m always struck by their dedication to lifelong learning. The field of metallurgy and materials science is constantly evolving, and these professionals are always at the forefront, devouring new research, attending conferences, and collaborating across disciplines.

It’s not just about theoretical knowledge; it’s about applying that knowledge in practical, tangible ways, often facing incredibly complex challenges with no clear-cut solutions.

Their expertise isn’t just about what they know; it’s about how they think, how they innovate, and their relentless pursuit of excellence that makes the impossible, possible.

It’s truly inspiring to see such sharp minds dedicated to advancing our world, one metallic marvel at a time.

The Unsung Heroes: Attention to Detail in Every Weld and Joint

While engineers design the components and materials, it’s the highly skilled technicians on the factory floor who bring those designs to life. I’m talking about welders who can create flawless seams in exotic alloys, machinists who can achieve tolerances finer than a human hair, and inspectors who can spot a microscopic flaw invisible to the untrained eye.

These are the unsung heroes of aerospace manufacturing. Their attention to detail is legendary, bordering on obsessive, and for good reason. Every weld, every joint, every surface finish has to be perfect.

There’s no room for shortcuts or “good enough.” It requires incredible patience, precision, and an almost artistic touch. I’ve watched these craftsmen work, and there’s a certain meditative quality to their movements, a deep understanding of their material and tools.

Their dedication to impeccable quality is a cornerstone of aerospace safety and performance, and without their exceptional skills, much of the innovation we see today simply wouldn’t be possible.

Beyond Our Atmosphere: Metal’s Enduring Legacy in Space Exploration

When we talk about venturing into space, it’s easy to get lost in the awe of rockets, satellites, and distant planets. But stop and think for a moment: what are these incredible machines actually made of?

Metals, of course! From the structural components of launch vehicles to the intricate mechanisms inside rovers exploring Mars, metals are absolutely fundamental to our cosmic ambitions.

The challenges are even more extreme out there – vacuum, extreme radiation, wildly fluctuating temperatures, and micrometeoroid impacts. It’s truly astonishing to consider how materials developed here on Earth are then engineered to survive and perform flawlessly in an environment that is utterly hostile to life.

Our ability to explore space, to send probes to the outer reaches of our solar system, and to dream of even further destinations, is inextricably linked to our mastery of advanced metallic materials.

This legacy is not just about getting there; it’s about surviving and thriving once we arrive.

Building for the Stars: Sustaining Life in Harsh Environments

Think about the International Space Station, a marvel of human engineering orbiting Earth. It’s a complex blend of advanced alloys designed not just for structural integrity in a vacuum, but also to protect its inhabitants from harmful radiation and extreme temperature swings.

Every single component, from the pressure vessels that hold life-sustaining gases to the radiation shielding on the exterior, relies on metals with very specific properties.

I often wonder about the sheer ingenuity involved in selecting and processing these materials to ensure that astronauts remain safe and that critical systems function flawlessly for years in such an unforgiving environment.

It’s a testament to the incredible foresight and scientific rigor applied to every single piece of metal that goes into space. We’re not just building vehicles; we’re building miniature, self-sustaining habitats for exploration, and metals are the bedrock of their existence.

The Next Frontier: Future Materials for Interstellar Travel

As inspiring as our current space achievements are, the true dream for many is interstellar travel. And when you start thinking about journeys that could take decades or even centuries, the material challenges become truly staggering.

We’re talking about materials that need to withstand constant radiation exposure, self-repair minor damage, and maintain integrity over unimaginable timescales.

I get goosebumps just thinking about it! This is where the boundaries of metallurgy are truly being pushed to their absolute limits. Researchers are exploring exotic concepts like metallic glasses for enhanced strength, self-healing alloys, and advanced composites capable of enduring interstellar dust impacts.

It’s a fascinating blend of theoretical physics and practical engineering, all aimed at crafting the vessels that will one day carry humanity’s hopes to other star systems.

The metals we’re developing today aren’t just for current missions; they’re laying the groundwork for a future that is still largely confined to our wildest dreams.

Sustainability on the Horizon: Greener Metals for a Brighter Future

It’s no secret that traditional manufacturing, including metalworking, has often come with a significant environmental footprint. But what’s genuinely encouraging, and something I’ve been following closely, is the aerospace industry’s growing commitment to sustainability.

It’s not just about making planes more fuel-efficient; it’s about rethinking the entire lifecycle of the metals we use, from extraction and processing to manufacturing and eventual recycling.

This shift towards “greener metals” is not just a trend; it’s an imperative, driven by environmental consciousness and economic savvy. I firmly believe that the future of flight isn’t just about faster or higher; it’s about cleaner and more responsible, and the innovations in sustainable metallurgy are absolutely critical to achieving that vision.

It’s a holistic approach, aiming to reduce waste, minimize energy consumption, and create a truly circular economy for these vital materials.

Recycling the Skies: Circular Economy in Aerospace Manufacturing

The idea of a circular economy for aerospace materials is genuinely exciting. Instead of a linear “take, make, dispose” model, the goal is to keep valuable metals in use for as long as possible.

Imagine an old aircraft being decommissioned, and its high-grade aluminum, titanium, or nickel alloys being meticulously recycled and re-purposed for new components, rather than ending up in a landfill.

This isn’t just theoretical; it’s becoming a practical reality. Companies are investing heavily in advanced recycling technologies that can separate and purify these complex alloys, ensuring their properties are maintained for re-use.

I’ve always been a big proponent of recycling, and seeing it applied to such high-value, high-performance materials in aerospace truly highlights its importance.

It’s a smart economic move, reducing reliance on virgin materials, and a crucial environmental step, significantly cutting down on energy consumption and waste.

It’s about creating a truly sustainable future for flight, right from the very beginning of a material’s life cycle.

Innovations in Eco-Friendly Production: Reducing Our Footprint

Beyond recycling, there’s a huge push to make the *production* of metals more environmentally friendly from the outset. This includes developing new processes that require less energy, produce fewer emissions, and generate less hazardous waste.

For example, advancements in electric arc furnaces for steel production or more efficient techniques for titanium extraction are all contributing to a smaller ecological footprint.

I’ve read about research into “green hydrogen” for metal production, aiming to replace fossil fuels in these energy-intensive processes. It’s a monumental challenge, but the innovation here is inspiring.

Furthermore, the shift towards additive manufacturing, with its inherent waste reduction, is another significant step. Every little bit counts, and these innovations in eco-friendly production methods are showing a clear path towards a future where our aerospace ambitions can coexist harmoniously with our planet’s well-being.

It’s about proving that cutting-edge technology and environmental stewardship are not mutually exclusive, but rather, can advance hand-in-hand.

| Material Class | Key Properties | Aerospace Applications | Environmental Advantage (Modern Usage) |

|---|---|---|---|

| Titanium Alloys | High strength-to-weight ratio, corrosion resistance, high melting point | Aircraft frames, engine components, landing gear, fasteners | Recyclability, extended lifespan reduces replacement frequency |

| Aluminum Alloys | Lightweight, good formability, cost-effective | Aircraft fuselage, wings, structural components | High recyclability, ongoing research in lower-energy primary production |

| Nickel-Based Superalloys | Excellent high-temperature strength, creep resistance, oxidation resistance | Jet engine turbine blades, combustion chambers, exhaust nozzles | Durability and extended service life reduce material consumption over time |

| Steel Alloys (High Strength) | High strength, hardness, fatigue resistance | Landing gear, actuators, high-stress structural parts | Improved manufacturing efficiency, increased use of recycled content |

| Composites (e.g., Carbon Fiber Reinforced Polymers) | Extremely lightweight, high strength, customizable properties | Aircraft fuselage, wings, control surfaces (often paired with metal fasteners) | Significantly reduces aircraft weight leading to lower fuel consumption; ongoing research into end-of-life recycling |

Wrapping Things Up

Whew! What a journey we’ve taken through the fascinating world of aerospace materials. It truly is incredible to peel back the layers and appreciate the sheer genius and dedication behind every ounce of metal and composite that takes to the skies or ventures into the cosmos. From the atomic dance within superalloys to the intricate layers of 3D-printed components, these unseen heroes are constantly redefining what’s possible in flight. It’s a testament to human ingenuity, pushing boundaries not just for performance but also for safety and an increasingly sustainable future. I always feel a renewed sense of awe after diving into topics like this, knowing that brilliant minds are tirelessly working to make our aerial dreams a reality.

Good-to-Know Information

1. Material Evolution is Continuous: Don’t ever think we’ve hit the ceiling! The quest for lighter, stronger, and more resilient materials is an ongoing marathon. Breakthroughs in nanotechnology and advanced manufacturing techniques are continually opening up new possibilities, meaning the aircraft and spacecraft of tomorrow will be built from materials we can barely imagine today.

2. Cost vs. Performance is a Constant Balancing Act: While innovation is exciting, engineers are always grappling with the economics. Exotic materials often come with a hefty price tag, both in raw cost and in specialized processing. The challenge is finding that sweet spot where performance gains justify the investment, ensuring that advancements can be practically implemented across the industry.

3. Sustainability is Now a Core Design Principle: It’s no longer an afterthought. Modern material development actively considers the environmental impact, from raw material sourcing to end-of-life recycling. This means not just more fuel-efficient planes, but greener manufacturing processes and a push towards a truly circular economy for aerospace metals and composites, which I personally find incredibly encouraging.

4. The Human Element Remains Crucial: Despite all the automation and advanced tools, the seasoned eye of a metallurgist, the precise hand of a welder, and the intuitive judgment of an engineer are irreplaceable. These human skills and the deep, experience-based knowledge they bring are what ultimately ensure the flawless quality and reliability demanded by aerospace standards.

5. Aerospace Materials Influence Everyday Life: The incredible advancements in materials science for aviation and space don’t stay confined to that realm. Often, these “supermaterials” and the processes developed to handle them eventually trickle down into other industries, from high-performance automotive parts to medical implants, making our everyday lives safer and more efficient.

Key Takeaways

What I really hope you take away from this is a profound appreciation for the silent, yet absolutely critical, role that materials play in revolutionizing flight. It’s a field brimming with brilliant minds, relentless innovation, and an unwavering commitment to safety and excellence. We’ve seen how everything from the atomic structure of an alloy to the precision of additive manufacturing contributes to the incredible machines that define modern travel and exploration. The synergy between material science, engineering, and human craftsmanship is truly what propels us higher, faster, and towards a more sustainable future in the skies and beyond. Always remember, the magic of flight isn’t just in the engines, but in every meticulously chosen, engineered, and crafted piece of metal.

Frequently Asked Questions (FAQ) 📖

Q: What are some of these mind-blowing advancements in metalworking that are truly changing aerospace right now?

A: Oh, where do I even begin? It’s absolutely wild to see how far we’ve come. For me, one of the most exciting breakthroughs has to be in advanced alloys.

We’re talking about materials like superalloys, often based on nickel or titanium, that can withstand incredible temperatures and pressures – conditions that would simply melt or shatter conventional metals.

Think about engine components in jet turbines or rocket nozzles; these materials are literally the difference between a successful mission and a catastrophic failure.

I remember reading about how engineers are even designing alloys at the atomic level now, tailoring their properties for specific extreme environments.

But it’s not just about what we can make metals do; it’s also how we make things. Additive manufacturing, or 3D printing, has been a game-changer. Suddenly, we can create incredibly complex, lightweight structures that were impossible with traditional casting or machining.

Imagine a rocket engine part with intricate internal cooling channels, all printed as a single piece. It cuts down on waste, reduces weight (which is gold in aerospace!), and allows for designs that are just mind-bogglingly efficient.

Honestly, seeing some of the intricate designs coming out of these processes makes me feel like we’re living in a sci-fi movie!

Q: It sounds like traditional metalworking isn’t just a thing of the past. How does that ancient artistry actually connect with today’s high-tech aerospace world?

A: That’s a fantastic question, and it really gets to the heart of what I find so inspiring! It’s easy to think of “ancient” and “high-tech” as completely separate, but my experience tells me they’re deeply intertwined.

When we talk about ancient metalworking, we’re talking about fundamental principles: understanding how heat affects metal, how to shape it, strengthen it, and how its internal structure dictates its performance.

Those core metallurgical insights, developed over millennia, are still absolutely crucial today. Modern engineers aren’t reinventing the wheel; they’re building on that foundational knowledge.

They’re taking the artisan’s intuitive understanding of materials and supercharging it with advanced science and computational tools. So, while we might be using laser sintering instead of a blacksmith’s forge, the goal is often the same: to create a piece with unparalleled strength, durability, and a specific function.

The difference is we now have microscopes, simulations, and advanced testing that allow us to achieve a level of precision and performance our ancestors could only dream of.

It’s like the ultimate collaboration between the master craftsman of the past and the brilliant scientist of today – each informing the other.

Q: Beyond just building better planes and rockets, what’s the real-world impact of all this? How is this metal magic genuinely shaping our future?

A: Oh, the impact is immense, far beyond just getting us from point A to point B faster or launching satellites. When I think about it, the ripples extend into so many aspects of our lives.

First off, there’s safety and reliability. Stronger, more resilient components mean safer flights and more dependable space missions. That alone is a massive win for everyone, whether you’re a passenger or an astronaut.

Then, consider efficiency and sustainability. Lighter aircraft consume less fuel, which not only saves money for airlines (and potentially lowers ticket prices for us!) but also significantly reduces carbon emissions.

In space, every gram saved means less fuel needed for launch, making space travel more accessible and economical. This opens doors for things like asteroid mining, building habitats on other planets, and developing advanced communication networks that could revolutionize global connectivity.

Personally, I get excited thinking about the sheer possibilities for scientific discovery and exploration. Better materials for telescopes, probes, and future spacecraft mean we can push the boundaries of what we can see and learn about the universe.

It’s not just about making things; it’s about enabling a future where we explore further, live smarter, and connect more deeply. This metal magic isn’t just building tomorrow’s hardware; it’s quite literally shaping tomorrow’s world for all of us.